|

|

|

|

|

|

|

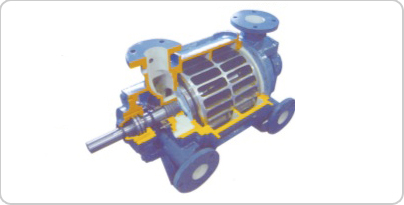

Flowtech Vacuum Pumps The Flowtech pump range has been specifically designed to withstand the rigours of industry where process liquids and solid particles may carry over into the vacuum pump, where the gas is explosive or contains corrosive vapours. Flowtech Vacuum Pumps have only one moving part, a solid cast Stainless Steel rotor mounted on a Stainless Steel shaft. This simple rugged construction ensures very reliable, low maintenance performance. The use of higher quality materials in the flowtech range provides the benefits of longer life and higher efficiency at no extra cost. The standard materials of construction can easily be upgraded at little extra cost to suit more agressive applications. The option include:

The wide range of options enable Flowtech Pumps to be economically matched to your process requirements. Shaft sealing by high quality gland packing is standard with a wide range of single, double and cartridge mechanical seals being available to meet environmental protection requirements. The Flowtech range has 12 sizes ranging from below 200CFM to over 13000CFM in suction capacity. Operating vacuums of up to 27.5 Inches of mercury (700mmHg) can be reached with the single stage design without the use of valves. Flowtech Pumps can be supplied as pre-engineered packages with extra equipment to meet process requirements and to reduce on-site assembly. A pre-engineered package could include:

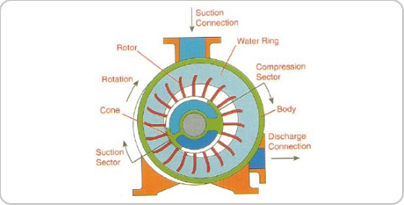

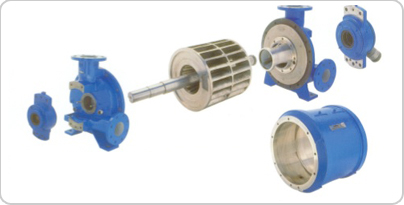

How it works the Flowtech design vacuum pump has only one moving part, a balanced Stainless Steel rotor. The 20 bladed rotor transmits power to the liquid inside the casing and causes a ring of liquid to be formed due to the centrifugal force created. Because the rotor is offset from the central axis of the body the liquid ring fills then empties the chambers formed between the blades of the rotor. In effect the liquid ring creates a "Piston like" pumping action. Gas enters and is discharged through the corresponding ports in the cones. The liquid ring also absorbs the heat of the compression and condensation of vapours, therefore cool liquid must be continually supplied to prevent excessive temperature rise and to replace the liquid which is discharged with the gas. The Flowtech Vaccum Pumps can be selected for optimum efficiency at high. medium, or low vacuum operation by changing the timing of the discharge port. Features of the Flowtech CN & CVP Pumps:

Flowtech Modified pumps cut costs, reduce downtime and increase productivity To keep your plant expenditure down, it is vital your pumps deliver efficient, reliable performance. Lost hours due to down-time can have a critical effect on your cash flow and profit. Not to mention the large costs associated with buying new pumps. Many companies are overcoming these problems and actually increasing efficiency by using the proven technology of Flowtech modified pumps. This attractive alternative offers the unbeatable combination of increased productivity benefits and lower initial costs. Many flow-on benefits of Flowtech Vacuum Pumps: Vital savings on purchase price. Not only can you buy a Flowtech modified pump at less than a new equivalent, but you will also have a superior pump. Vital savings on cost. Flowtech Vacuum Pumps are completely revitalized and modified using the most advanced technology for improved performance. All wearing parts such as bearings and seals are replaced. Tolerances between rotor and cones are precision set using special assembly techniques to ensure maximum performance. More importantly, all surfaces subject to wear or exposed to process fluids are specially coated for extra protection and longer life. So, unlile a new pump, a Flowtech modified pump is protected against wear, increasing its efficiency and working life. Flowtech customers have reported that they have achieved better vacuum than new units. Vital savings on service and power costs. The three enemies of liquid ring vacuum pumps are corrosion, cavitation and erosion. Corrosion in the form of rust or chemical degradation continually exposes bare metal surfaces to attack from cavitation and erosion. However, pumps modified by Flowtech are protected against erosion resulting in increased service life. In fact, Flowtech modified pumps have a service life often exceeding new units. In addition, this special inner surface treatment reduces friction which means liquid flows more easily, reducing power consumption. Vital savings on down-time. More than disrupting operations, down-time can affect your cash flow and bottom-line profit. Also, ordering a new pump can involve long delays in delivery. With Flowtech, costly problems such as these are virtually eliminated. A wide cross-section of modified-reconditioned, fully-guaranteed pumps are available ready for immediate use. This provides you with access to suitable pumps to replace damaged units or meet production demands. Flowtech pumps are dimensionally compatible with most existing systems so fitting difficulties are minimized. With Flowtech, down-time is reduced to an absolute minimum and productivity is maintained to a maximum.

|